Underwater Painting

Seaward has been the U.S. Navy’s prime contractor for underwater hull cleaning, inspection, non-destructive testing, and repairs since 1979. Our average annual diving services workload, for Navy and commercial ships, exceeds 900 ships per year.

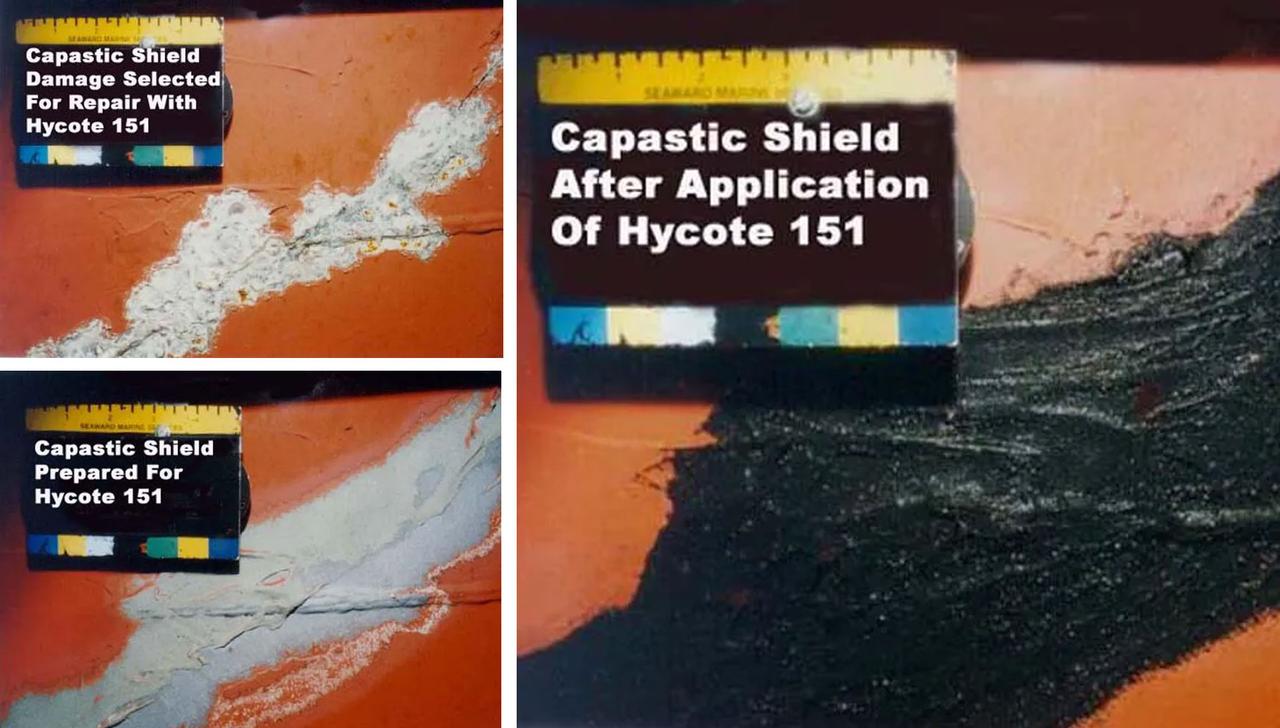

Seaward was instrumental in developing and refining a solution to underwater structure preservation and corrosion problems. Seaward uses the HYCOTE underwater paint formulation, which features a unique 2-part epoxy coating which is specifically designed to be applied in wet environments.

The system is tolerant of a wide range of ambient temperatures and does not require a prime coat. The cured coating has excellent resistance to a wide range of chemicals and has a hard, smooth finish with a very low drag co-efficent.

Special Features

The coating has within its range of normal usage the standard above-water protection of metal in processing plants, marine and offshore environments, tankage and shipping. It has the special characteristic of being able to be applied underwater and therefore is ideal for application in high humidity, to wet surfaces and during inclement weather.

Efficient Application

- No primers required

- Allows a wide range of coating thickness by single or multiple coat application

- The normal single coat application saves time and cost

- Well designed plural component application equipment reduces materials wastage

In Special Environments Around The World

- Underwater

- Wet surfaces

- High humidity

- Inclement weather